2025 Particleboard Conference

October 09, 2025

October 09, 2025 Hits:222second

Hits:222secondBreaking Through with Surface Technology! Making Particleboard's “Surface” More Competitive

September 24-26, 2025, the 2025 Particleboard Industry Innovation and Development Symposium was held in Longli, Guizhou.Ms. Fu Qiuxia, Chairwoman of Guangdong PURETE Mechanical Co.,ltd delivered a presentation titled “Differentiating Particleboard Surface Finishing Technologies.” Drawing on her deep industry insights and practical experience, she centered her discussion on “differentiated surface finishing technologies” to deconstruct breakthrough strategies for the particleboard industry: — While ensuring the quality of the substrate (“substance”), it is equally crucial to leverage the surface finish (“appearance”) to build barriers, reduce costs, and expand markets, providing new tools to break through industry-wide competition.

I. Industry Reflections from a “Facade Solutions Innovator”

As a five-year participant in the Particleboard Conference, Director Fu reflected on Purite's connection with the particleboard industry:When she first entered the field in 2021, she observed that the tile industry's end-to-end investment in “forming + surface finishing” offered valuable lessons for particleboard manufacturers. Having already invested billions in forming equipment, adding tens of millions in finishing machinery would address the industry's “surface quality” shortfall. At the 2023 Wuhan conference, she introduced the “earn two cups of Maotai coffee per board” technology: adding a coating layer to particleboard enables direct double-sided PET lamination, eliminating the need for balancing paper while preventing warping. This allows downstream door panel manufacturers to skip straightening equipment, creating a win-win for both enterprises and customers.

The past five years have been a challenging period for the particleboard industry. Chairman Fu candidly admits that profit margins for particleboard manufacturers have visibly compressed. To break through this impasse, companies have had to “complicate their own operations”: developing more production lines and investing in additional teams, all to simplify applications for downstream customers. This dialectic of “complexity and simplicity” embodies Hanqiu's founding mission in specializing in surface coating equipment.

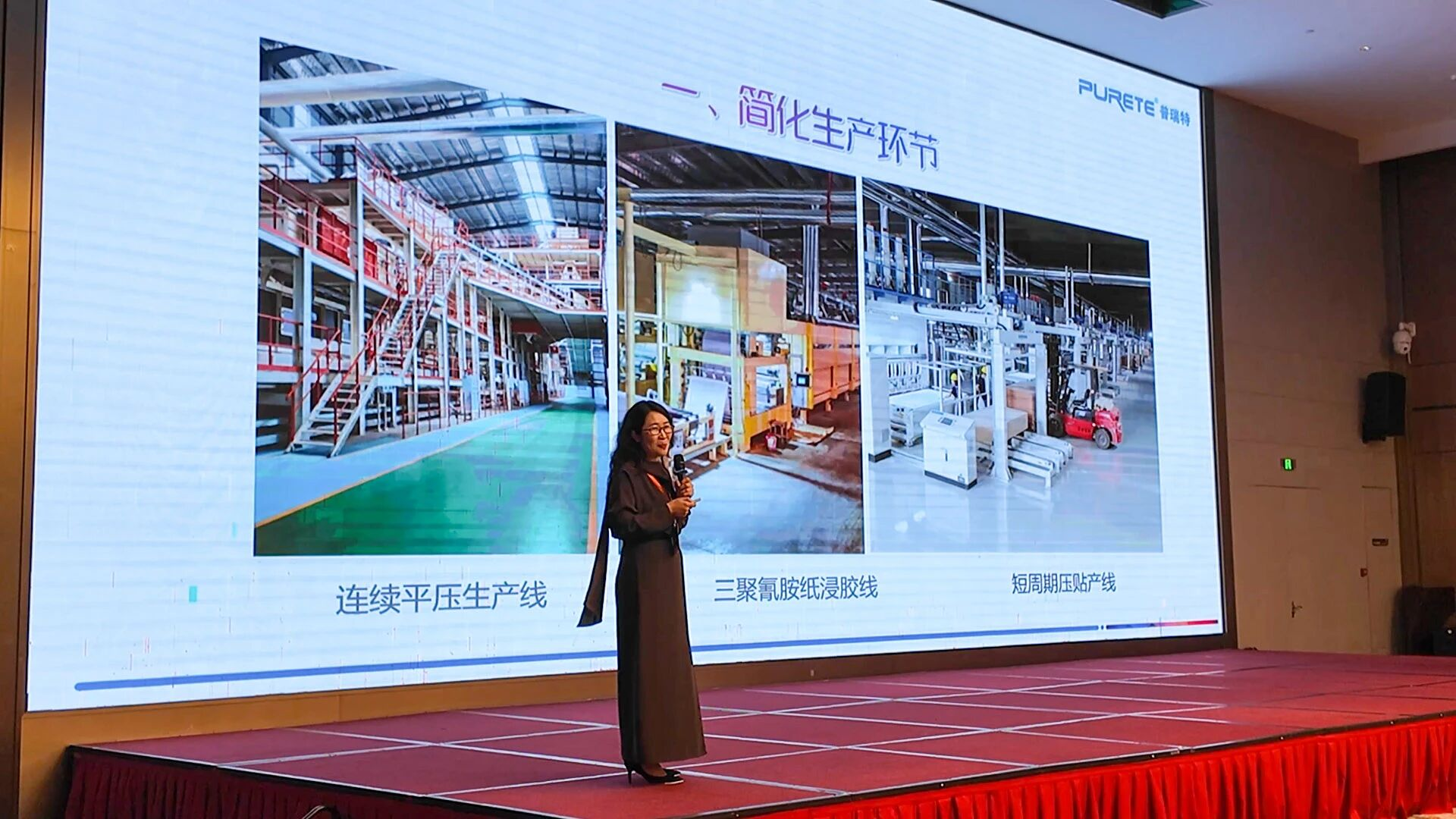

II. Three Major Surface Finishing Technologies: Deconstructing the Core Competitiveness of Particleboard “Facing”

Mr. Fu categorizes particleboard surface finishes into paper-based, film-based, and paint-based materials, summarizing the industry landscape with a “70:20:10” market share ratio. He highlights the key technical points within:

Lacquer Materials (10% Share): Though accounting for a small proportion, lacquer materials possess strong high-end attributes. From applying wood veneer to raw panels and finishing with UV matte lacquer to milling shapes and spraying solid-color PU lacquer, the complex craftsmanship yields a premium aesthetic.

Film Materials (20% share): PET/PP film lamination is the mainstream approach. For shaped products, wrapping and flat lamination techniques are employed to meet the diverse customization demands of furniture.

Paper Materials (70% Market Share): Paper materials, primarily short-cycle laminating, represent a large market volume. Recently, Juerisen has deployed 20 laminating lines in a single workshop, while Luli has procured over ten lines. Concurrently, embossing and deep embossing enhance texture, with seven-foot/nine-foot wide-format production lines emerging as a new trend.

III. Differentiated Breakthroughs: How Should Three Types of Enterprises Proceed?

For core material manufacturers, decorative surface enterprises, and surface material producers within the particleboard industry chain, Director Fu offers precise solutions to break through challenges:

Substrate Manufacturers:

① Streamline production processes (continuous flat-press production lines, melamine paper impregnation lines, short-cycle laminating lines)

② Reduce operational costs (lower logistics and electricity expenses, enhance material utilization rates)

③ Establish high barriers to entry (high-threshold production line investments, large-scale production line investments, full-chain production line investments)

Finishing Enterprises:

④Diverse materials broaden customer base (wood products, metal products, plastic products, cement products)

⑤Multiple processes accommodate varied preferences (flat roll, flat spray, flat press, flat laminate)

⑥Versatile applications fulfill diverse requirements (flat panels, grilles, arcs, moldings)

Surface Material Manufacturers:

⑦Embrace branding for expanded collaborations

⑧Diversify patterns for increased development (stone-effect surfaces, wood-effect surfaces, fabric-effect surfaces, solid-color surfaces)

⑨Differentiated finishes for higher market barriers (distinctive effects, differentiated performance, specialized applications)

IV. Conclusion: Capable of Rolling, Spraying, Pressing, and Laminating

“We must make ourselves more complex to simplify things for our customers.” This statement embodies both Hanqiu's founding mission in intelligent equipment and the essence of particleboard industry evolution—only through continuous innovation in surface finishing technology can particleboard transform from a “commodity” into a “high-value-added product,” meeting the diverse demands of downstream custom furniture and interior decoration. Moving forward, Hanqiu will remain committed to its core “paper-based, film-based, and paint-based” finishing technologies. We will focus on industry pain points, explore superior process solutions, develop more categories of intelligent coating production line equipment, and collaborate with partners across the particleboard supply chain to innovate coating technologies and create a better life together!