2025 The Shanghai Home Furnishings Expo concluded successfully.

September 18, 2025

September 18, 2025 Hits:287second

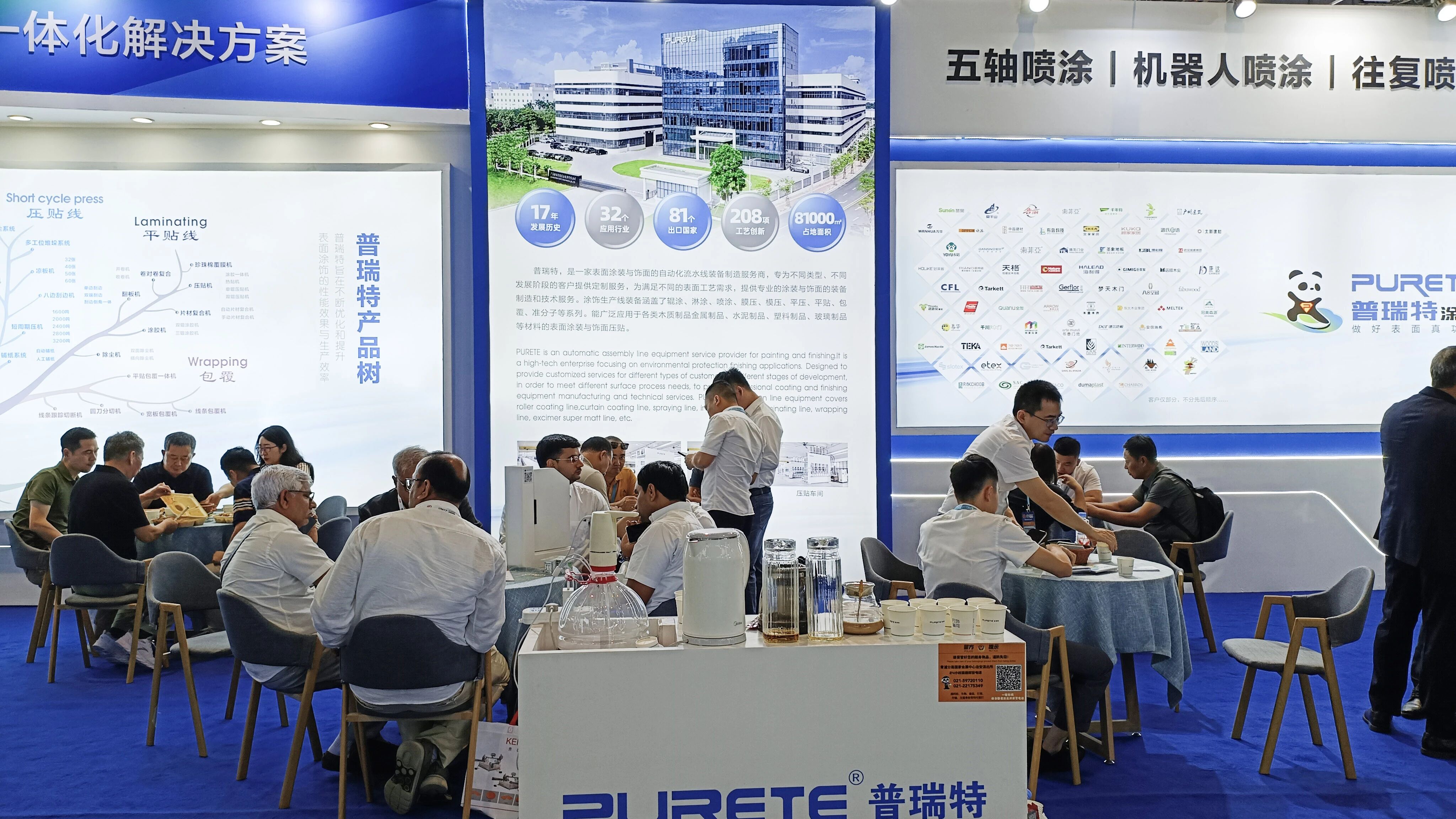

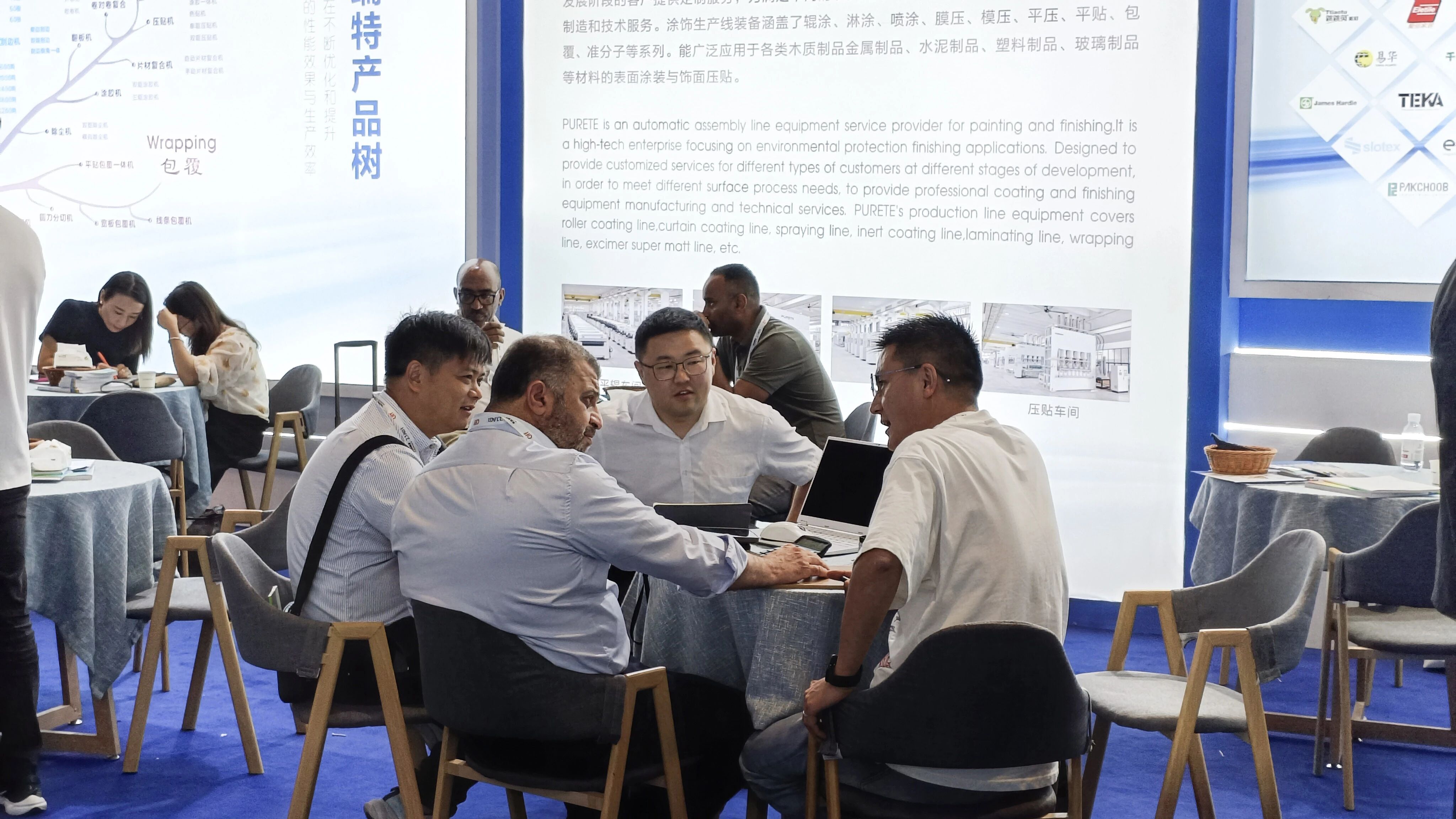

Hits:287secondOn September 12, 2025, the Shanghai Home Expo and WMF International Woodworking Fair successfully concluded its four-day run at the National Exhibition and Convention Center. With the theme of “Rolling, Spraying, and Laminating”, Guangdong Hanqiu Intelligent Equipment Co., Ltd. showcased its integrated surface finishing solutions, which became a highlight of the exhibition and injected fresh momentum into the industry’s drive toward intelligent upgrading.

Highlights Review

One of the major highlights of this exhibition was the keynote speech delivered by Mr. Chen Zejin, General Manager of Hanqiu’s Business Division, at the China (Shanghai) International Furniture Production Equipment and Woodworking Machinery Fair. His presentation on “Innovative Technologies for Multi-Material Applications” directly addressed the pressing challenges of “material diversification and process complexity” faced by today’s furniture industry.

In his speech, Mr. Chen emphasized that with consumers’ demands becoming increasingly diverse, traditional home products featuring a single material or uniform style can no longer satisfy market needs. Instead, personalization and customization are emerging as mainstream trends. The “multi-material” concept advocated by PURETE covers four major substrates—metal, plastic, wood, and cement—for which the company provides a wide range of coating and surface finishing solutions.

Release of Innovative Multi-Material Technologies

Rolling | Spraying | Laminating

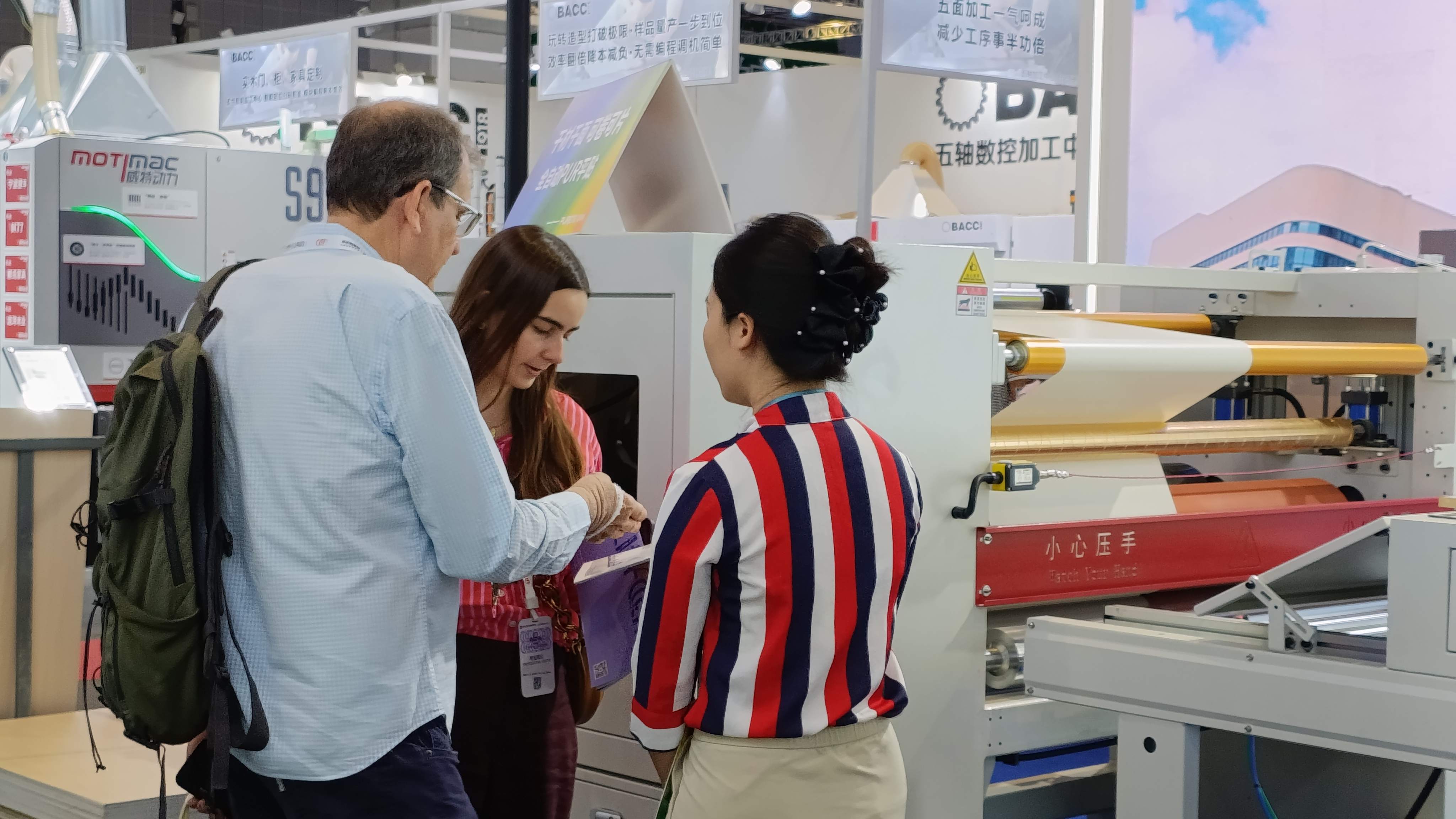

At this exhibition, Hanqiu’s reciprocating spraying machine and PUR flat lamination line, as the core equipment of its integrated surface finishing solutions, received wide acclaim from customers.

The PURETE reciprocating spraying machine is equipped with an intelligent paint control system that automatically adjusts spraying parameters according to the size and material of the workpiece, effectively avoiding paint waste and saving over 20% more paint compared to traditional equipment. At the same time, the machine is fitted with high-precision guide rails and servo motors, achieving a spraying accuracy of ±0.1 mm, ensuring every workpiece receives a uniform and smooth coating while overcoming the common issues of color inconsistency and low efficiency in manual spraying. Whether it is large surface panels or complexly shaped workpieces, the system handles them with ease.

PUR Flat Lamination Line: Strong Bonding, Eco-Friendly & Durable

The PUR lamination line focuses on upgrading the bonding process, utilizing eco-friendly PUR hot-melt adhesive with zero formaldehyde emissions, fully compliant with national environmental standards. During lamination, intelligent temperature control and pressure adjustment ensure an even adhesive layer, delivering a bonding strength 30% higher than traditional cold glue, along with superior heat and moisture resistance that prevents delamination even in humid environments. In addition, the equipment supports bonding with a variety of surface materials such as PVC, PET, and natural veneer, meeting furniture manufacturers’ needs for multi-purpose production with one machine.

An End Marks a New Beginning

The conclusion of the WMF International Woodworking Fair marks not only another milestone in Guangdong Hanqiu’s dedication to the surface finishing equipment sector, but also a new starting point for the future. Although the exhibition has come to an end, PURETE’s path of innovation never stops.

With a 3,000-square-meter finishing experience center in Shunde and over 30 newly developed finishing processes, the company will continue to showcase the forefront of industry innovation to its customers.

We look forward to the next gathering, where PURETE will present even more innovative technologies and solutions.Innovative finishing technologies, creating a better life together!